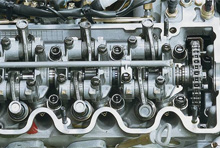

The sustainable development strategy of the global economy places more emphasis on the harmonious relationship between "people and nature", which in turn determines that the main direction of future technology research and development in the automotive industry is inseparable from the theme of "safety, environmental protection, and energy conservation." As a supporting material for automobiles, automotive greases can play an important role in the safety, environmental protection and energy saving of automobiles. We must grasp this general direction when developing new automotive grease products. And Jia Dan Kermo also carried out major technical research and development in the automotive grease. When it comes to safety, the most important thing about grease is reliability. As a component of a mechanical part, it must be reliable in itself. That is to say, it does not deteriorate in the natural environment, it is not easy to deteriorate under the action of temperature, load, medium and machinery or current in the working environment, and it should maintain the performance it should have within the time limit specified in the design of the part, and leave room for it. Just like the safety factor of other mechanical parts. In order to achieve this, at the beginning of new product development, it is necessary to fully analyze and use all the information that can be collected, including text information and physical information, combined with China's resource conditions, carefully design the development route according to the use requirements, and use the required performance tests. Means to screen and evaluate samples. It is worth emphasizing that in addition to physical and chemical performance testing, special attention should be paid to simulated mechanical tests, component tests, bench tests, and road driving tests. The friction and wear lubrication mechanism of any automobile component is extremely complicated, especially for grease lubrication which is mainly in the boundary lubrication condition. These tests are gradually approaching actual use, the more difficult and the higher the cost. Generally, do as much physical and chemical performance testing and simulated mechanical testing as possible, and accumulate the relationship between the two and the bench test before finally performing the road driving test. As far as environmental protection is concerned, the grease itself should try to use components that do not pollute the environment to avoid pollution to soil and water sources after leakage or discard. The minimum requirements are (or low toxicity) and biodegradable. For example, lead compounds used to increase the extreme pressure and water resistance of greases are potentially toxic to nerves and reproduction, and lead-free components have not been used in lubricating greases since the 1970s. The "green" extreme pressure element that replaces lead is bismuth, which does not cause ecological problems. The le...

Dongguan KEERMO Grease Co., Ltd. official website is officially opened After three months of preparations, Dongguan KEERMO Grease Co., Ltd. has completed the construction of the international official website. The company has established a foreign trade team to officially enter the international market in the domestic market. Looking forward to providing foreign customers with better grease products and professional grease customization services. The only domain name of KEERMO's official website is: WWW.KEERMO.COM KEERMO special grease, more than lubrication! Any questions, please contact us! Email: Leo@keermo.com

86-13380181800

86-13380181800 Leo@keermo.com

Leo@keermo.com

86-13380181800

86-13380181800

86-13380181800

86-13380181800